BREAKTHROUGH IN LASER SCANNING DATA PROCESSING FOR UNDERGROUND MINE SURVEY

With the current requirements for all underground mines to increase productivity, reduce costs and improve safety the role of technological innovations is ever increasing. For instance, speedy and efficient processing of data generated by an operational underground mine is an important tool to increase mine’s productivity and improve the quality of decision making. Quick and precise survey of developed mine workings and extraction cameras is an important part of an efficient production workflow. For a long time underground mine survey had been one of the most conservative part of mining. Until recently theodolite and surveyor’s rack were the main tools of any mine surveyor.

New technologies were few and far between and even more seldom there had been the attempts for them to be adopted for use in mining. The situation changed drastically few years ago due to the appearance of mobile laser scanning systems and subsequent reduction in the costs of scanning equipment.

The use of mobile laser scanners allows the extremely rapid generation of actual 3D model of an underground mine working (in comparison with manual / static methods) and almost instant visualization of mine survey results on computer screen.

However, the technological breakthrough in relatively cheap laser scanners appearance on the market has not led to their proliferation for everyday practical use in underground mine survey yet.

The problem is that the existence of few reasonably priced underground mobile scanning systems has not been followed by the development of universal data processing and data integration software to generate accurate 3D models of mine workings that are correctly geo-referenced to the mine survey network.

TUNNEL PRO-VISION system assists mine surveyor with efficient processing of mobile laser scanning data as well as with well-organized data management tools to track all mine development history, changes in mine plans and schedules, volumes of mining and development works.

Basic functionality:

- Import of data collected by any scanner either in a static or mobile mode

- Ability to work with unlimited file sizes

- Efficient point cloud visualization without the use of point color and intensity

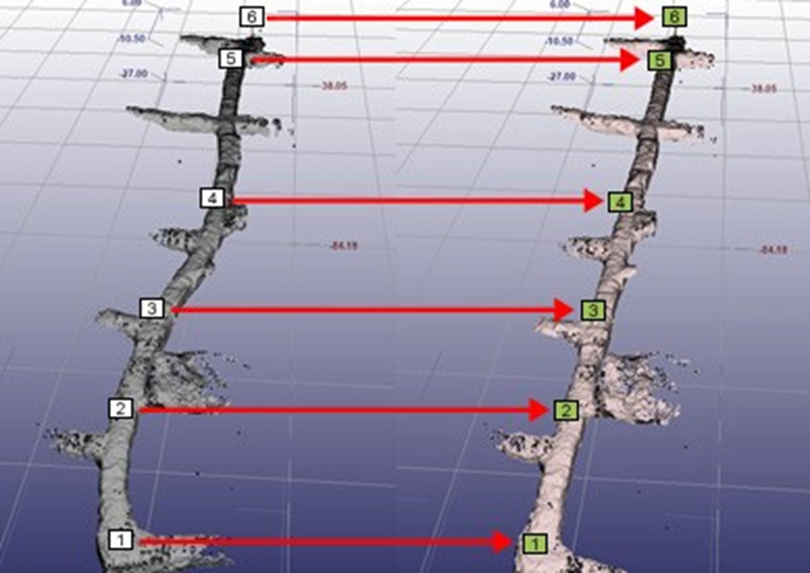

- Scan geo-referencing to the existing mine survey network with IMU drift compensation and the correction of cumulative deviation error

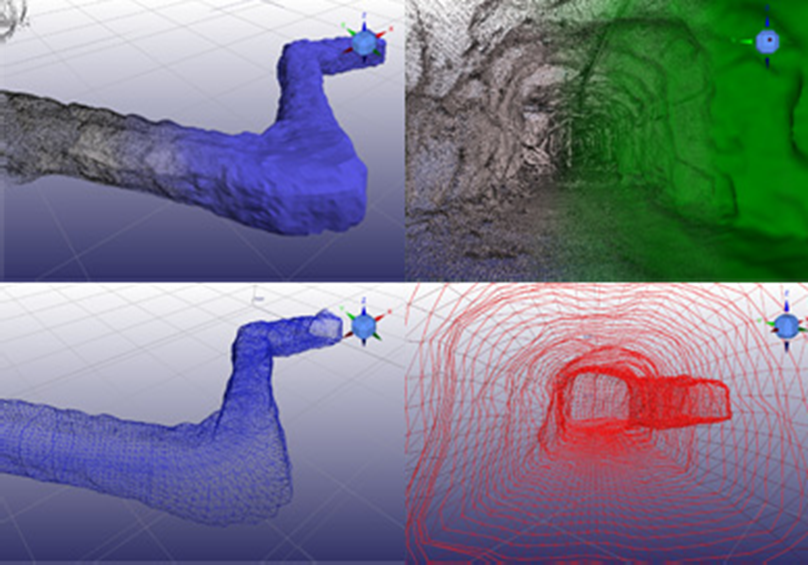

- Automatic mine workings’ surface generation, conversion of any scan to 3D CAD model

- Mine working volume calculation

- Cross-sections generation

- Export of 3D models and cross-sections to standard engineering formats

Extended functionality (Integrated data base of actual mine workings):

- Generation and editing of mine survey points data base

- Generation of topologically integrated actual mine model based on survey network and 3D models of mine workings geometry

- Multi-user mode

- Mine 3D model visualization through web-interface